Production Control

From processes to products, make it right the first time.

"This is so simple and clean."

"It was great to hear about all the ways that CIMx could help improve our processes. We all came away from that meeting blown away! Definitely looking forward to next steps."

A SINGLE SYSTEM FOR PRODUCTION OPERATIONS

Process Design

Design one or more processes from simple routings to complex sets of integrated process steps. Ensure that every step of your process is followed.

Engineered Parts

Create your product designs and the process to manufacture them, whether it's a simple routing, a job packet or a complex set of integrated process steps.

Process Manufacturing

Control basic and complex process-driven manufacturing with a platform that gives you the tools to both design them and run them.

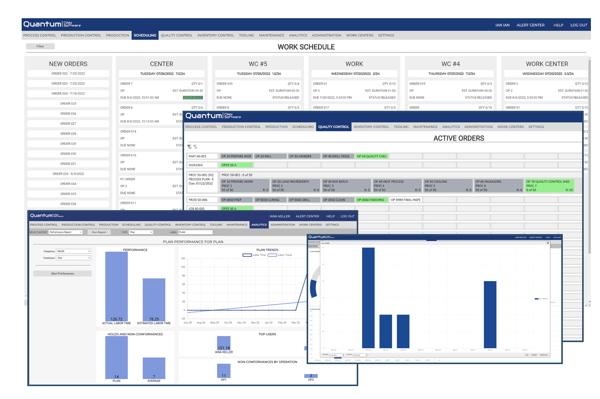

Production Scheduling

Push all your work to your shop floor automatically in the right sequence to make it profitable and know that it will be done on time.

Inventory Management

Track every material, part, sub-assembly and tool used throughout production for complete, end-to-end traceability for industry and customer compliance.

Process Control

Manage every step of the processes you are running on your shop floor, whether it's a simple routing, a job packet or a complex set of integrated process steps.

Quantum is built for production.

Production Control

Manage every job on your shop floor on-time without opening a spreadsheet or tracking down a routing, whether you have one big job or 1,000s all at once.

Quality Control

Demand complete compliance with your processes and your audit requirements. Reallocate work automatically or on-demand with the touch of a button.

Business Analytics

Make your factory SMART with tools from design through automated data capture. Get the data you need when and how you need it with the touch of a button.

Reporting

Know how everything's going without waiting until its done. Get rapid and real-time reporting that gives you the information you need to make decisions mid-production when required.

Asset Maintenance

Machine uptime is critical for your production. Get notifications of maintenance due, run planned maintenance and pick the right time on your schedule to do the work.

Asset Calibration

Get the record-keeping you need to track calibration records and ensure that your tools are properly set for the work you need them to do. Prevent tool usage past calibration requirements and really control your shop.

Dispatching

Get every Order onto the shop floor without having to manage the process. Put the work where it needs to go and ensure that it will be done on time.

Dashboards

Get an immediate view of the work on the shop floor and its progress towards completion. Quantum does all the heavy-lifting for you as you do your daily work.

Alerts

Ensure every member of your shop can communicate with the right team(s) without wandering around. Send alerts or just leave notes for future shifts.

Award-winning product and team.

Quantum and CIMx have been recognized by our customers and the industry for our product and our service.

CIMx was recognized as a LEADER in the 2022 InfoTech Research Group MES Software Survey and awarded #1 in VENDOR SUPPORT among all competitors. All vendors were rated by their own customers across capabilities, product features, and customer experience for this survey. The people have spoken.

.png?width=480&height=149&name=CIMx-logo-transparent%20(1).png)