Issue 6

Welcome to Qubits!

Exploring the full capabilities of QUANTUM Software and how it helps address your PRODUCTION CONTROL needs.

This issue is focused on

BEST PRACTICE PRODUCTION PLANS

In many large companies, there is an organization whose function is to develop and standardize “best practices” in production processes. A "best practice" is simply the best way to do something on a given machine, with a given tool, or within an assembly operation.

This work is vital to attaining optimum production capacity with consistent quality and can greatly improve operations in companies of any size. Quantum is designed to support best practices as they are developed by a company.

Imagine providing a product plan for an order that already contains answers to the most common (and uncommon) questions an operator on the shop floor might ask when it was rolled out to production. For example, an operator receives digital instruction at a machine which includes a complete plan with accurate work instructions, the quality checks needed so that all tolerances will be met, the correct tools needed, and the set-up sequence. In addition, there may be a one- or two-minute video illustrating how to go about the set-up and execution. There may also be a simple click for the operator to see detailed specifications or any other information helpful to perform the work on the order.

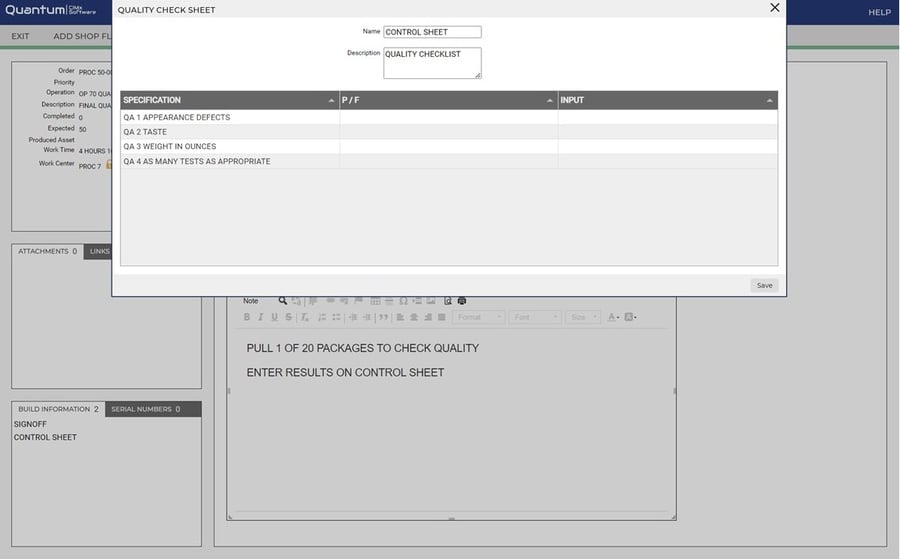

Detailed, Accurate Work Instructions

A best practice in Quantum is to include all the possible assistance a production person needs to do the work so that they can perform work quickly and accurately. Quantum has many time- and cost-saving options to provide as much critical information as possible to avoid the operator spending time asking others about how to do something or where to find a specification.

And, best practices can be developed over time and added when complete to Quantum Process Plans. The time invested to create these aids will be rewarded with capacity and quality improvements.

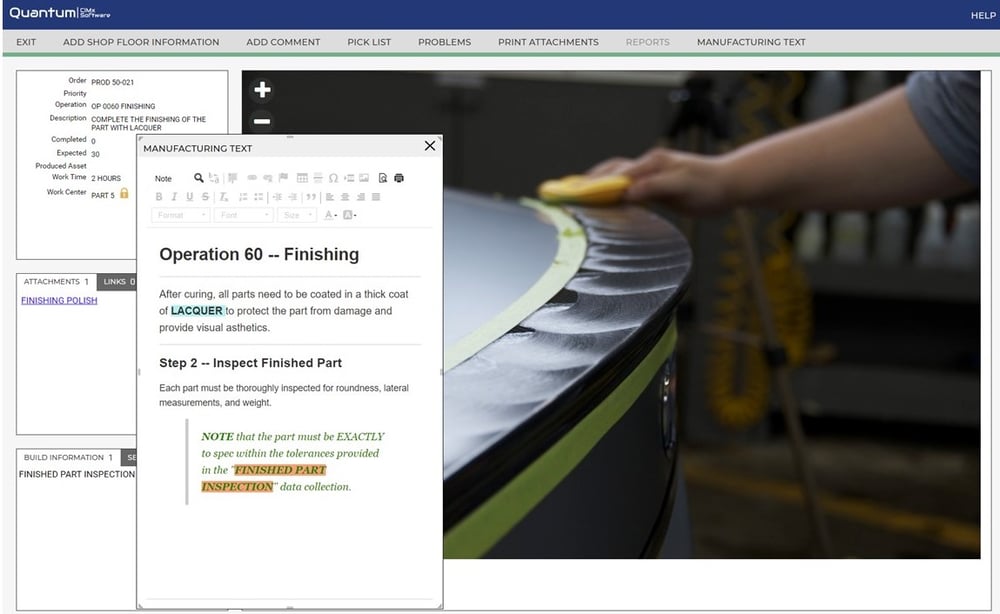

Include photos or video tutorials to increase operator understanding and speed

Imagine making a brief video (just a few minutes) on a smartphone of your best operator performing a process such as a machine set-up or an assembly of a complex product. Then, place that video in your best practice folder on the network and make it readily available inside your digital work instructions to anyone needing it on a future order.

A possible 20-minute investment of time, creating a handful of instructional videos, may save hours of time along with fewer quality defects and scrap for years to come. By ensuring your production operators have all the vital information they need upfront to do their job correctly the first time, they will inherently raise their skill levels and feel empowered in their work. Allowing them to work at their best and increase shop capacity.

Detailed, best-practice production plans that include visual instruction speeds up operator understanding to empower and quickly improve the skills of your production team. Increasing accuracy, efficiency and capacity.

If you would like to learn more about optimizing your production plans in your environment. Reach out.

We are here to help you get the most out of your Complete Production Control solution - Quantum.

Respectfully,

Your CIMx Software Team