Issue 8

Welcome to Qubits!

Exploring the full capabilities of QUANTUM Software and how it helps address your PRODUCTION CONTROL needs.

This issue is focused on

A COMPLETE ACCURATE DATABASE

When most people use a software productivity tool, they only take advantage of a subset of the capabilities provided. It’s typical for users to learn only what’s needed to do the common tasks they require. Or, they focus primarily on fixing a problem or set of problems that lead them to purchase the tool in the first place.

For example, what percentage of MS WORD or MS EXCEL capability do you use? It’s probably less than half or even below 20 percent. There’s no problem with that if you get the work done, but what capabilities are you missing out on that could increase your efficiency and boost your overall productivity?

Manufacturing production operations is a complex, daily changing process requiring a steady flow of decisions and compromises to achieve the results needed. Effective management of this environment requires an ever-changing set of current data.

Quantum can provide you with a complete accurate database of all current production activities. If you have not taken full advantage of it, we can assist you with simple process improvement suggestions to increase efficiency, quality control, and production capacity.

Capture and Track Work, Improve Quality with Process Reinforcement

Using a few additional capabilities in Quantum can add significant benefits to your results. Engineering production plans can create an up-to-date 5W2H database to enable “best solution” decisions when needed on a daily basis. For example:

- WHO worked on each operation of each order,

- WHAT did they do on that order, the process and inventory used,

- WHERE was the work performed, the work center or machine,

- WHEN was the work performed,

- WHY was it done that way and were there any deviations from standards,

- HOW was it done and were there any defects or tolerance violations,

- HOW long did it take.

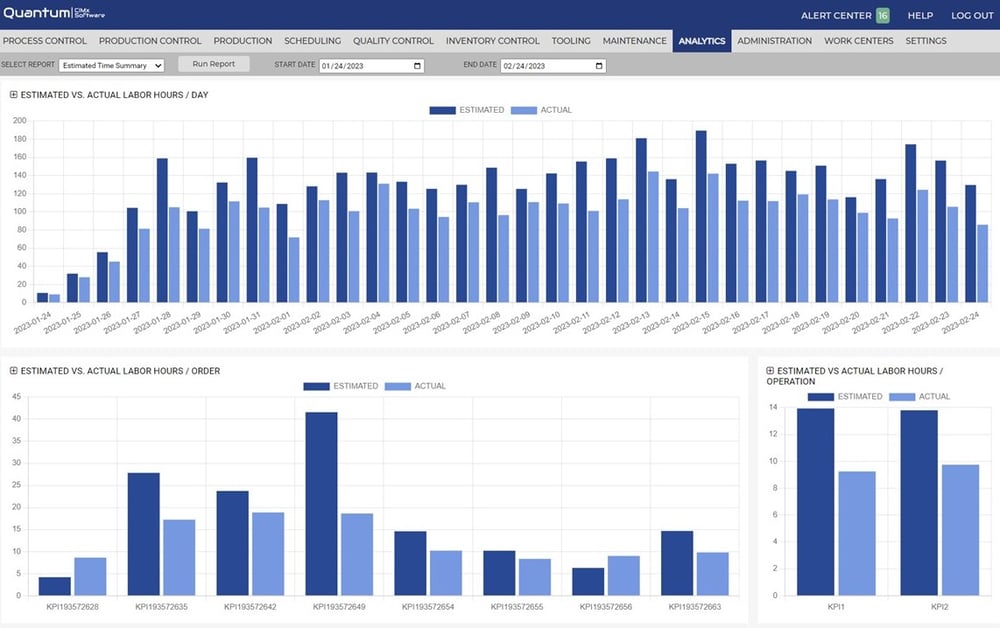

Obtain True Production Performance Information (estimated vs. actual) with Analytics

The capability to collect this data exists in all recent releases of Quantum. In addition, the Analytics subsystem processes this information to create greater than 44 reports (see Qubits Issue 3) on efficiency, capacity, the effectiveness of training, and more. There is also a custom reports generator for users with needs not covered by the pre-loaded reports. All reports can be used to improve operations in simple ways with large resulting benefits.

Quantum is designed to meet your workflow needs and help you continually improve your business results.

If you would like to learn more about how Quantum supports your team throughout the production process. Reach out.

Respectfully,

Your CIMx Software Team

Discover more issues of Qubits below or a full directory online.