Issue 2

Welcome to the second issue of Qubits!

We hope you enjoyed the first issue of the new CIMx newsletter that explores the full capabilities of Quantum and how it helps you address your Production Control needs.

Last month, you learned that Quantum offers 4 different Scheduling Options to better fit your unique production schedule. Did you miss it? Read about it here: Issue 1

In this issue, we discuss the importance of accurate Inventory Management and how Quantum automates and controls this data in real time so you know what you have at all times. Let's dig in.

This issue is focused on

INVENTORY MANAGEMENT

Trying to manage your inventory on paper or spreadsheets is cumbersome and error-laden because inventory is not being adjusted as it is being consumed. Who has time to count their inventory at the end of each shift or day? When it comes to inventory, you should know what you have at all times because inventory shortages cause delays in production, panic in purchasing, and profit loss with work stoppages and expedited shipping costs. Not a scenario anyone wants! There is a better way to keep inventory levels steady and its data current inside an ERP or MRP system. It’s Quantum.

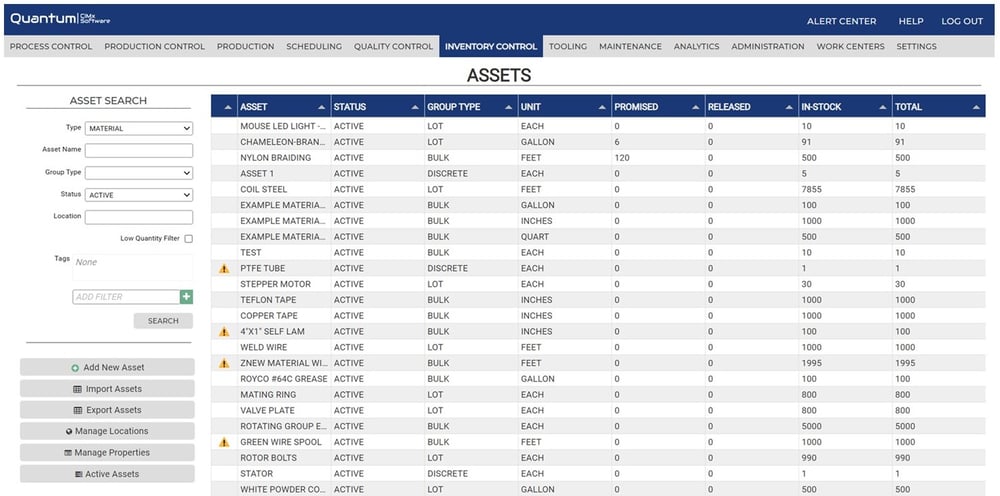

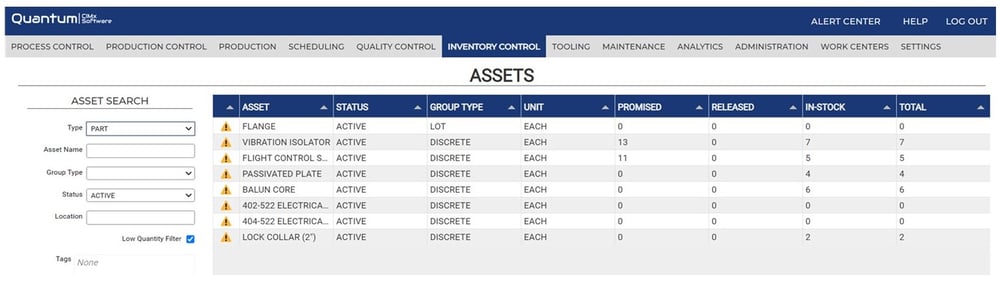

Quantum solves the inventory problems of too much or too little and allows the time taken for manual counts to be better used elsewhere. Serialized, lot, and bulk inventory are managed by Quantum to assure the accuracy of each special type. Quantum uses its standard integration to download your current ERP/MRP inventory data including boxes just being recorded at receiving. Quantum then records all consumed inventory in all orders daily and can update the ERP records each night to maintain an accurate record.

Alternately, the record in Quantum can be used to manage inventory. Quantum will maintain a high and low threshold. The high threshold alerts when excess inventory is being ordered; saving costs. The low threshold alerts that new inventory must be ordered; avoiding shortages. Quantum also tracks any “build to stock” inventory for future orders and maintains serialized inventory if needed.

Quantum works behind the scenes planning, capturing, managing and analyzing your production data. It can save most, if not all, existing costs of managing, counting, and correcting inventory including the cost of delayed orders.

How are you doing with Inventory Management in your shop? Could it be improved? Why not look at the intuitive options that are available with Quantum since you already have the solution in place?

Would you like to talk about this further? Let us know by clicking the button below.

Respectfully,

Your CIMx Software Team