machine maintenance

maximize uptime, minimize surprises

machine maintenance

maximize uptime, minimize surprises

prevent breakdowns before they happen

Unplanned machine downtime is one of the most expensive problems on the shop floor. Without a structured maintenance process, small issues go unnoticed until they stop production cold. Repairs take longer, orders pile up, and your capacity take a hit along with your reputation. Without machine maintenance:

✘ Unexpected breakdowns halt production and delay shipments

✘ Repair costs spike from emergency service calls and rush parts

✘ Machine performance slowly degrades, reducing throughput and quality

✘ Maintenance records are incomplete, making audits and planning harder

✘ Replacement schedules are missed, shortening equipment lifespan

Quantum gives you a proactive approach to maintenance to keep your machines running at peak performance, extend their lifespan, and eliminate costly surprises on your production floor.

.png)

machine maintenance with Quantum

Set and keep maintenance schedules, reducing the need to do emergency maintenance.

maintenance optimization

Optimize every asset you have in production and in inventory with real-time maintenance schedules and usage. Quantum records the use of every asset on your shop floor and ensures the calibration records, usage records and even time-out records are compliant. Reduce the cost of inventory when you are able to fine-tune the assets that you have and their scheduling.

control machine downtime

Ensure that every machine you have and every asset that you own is running optimally with Quantum. Track your maintenance schedules and build maintenance into your actual production schedule based on machine usage rather than every X days. If a machine breaks down, automatically reroute the work to another work center and get a real-time estimate of that lack of resource on your daily schedule. Don't just guess that you'll be behind. Know exactly where.

reduce defects and scrap

Proper machine maintenance and asset care is required to keep scrap rates low. Sharp blades, calibrated tools and well-oiled and clean machine are table stakes if you want the first product that comes off the production run to be just like the last one. Keep your production smooth and stable and drive your scrap rate down to near-zero with Quantum.

what's possible with Quantum

optimize machine use

When you know and keep proper maintenance schedules and records, you know that the machines you have can run at their proper cycles. Whether you need to run daily maintenance on a machine or do intermittent maintenance every 10,000 cycles, track it and complete the work in Quantum.

minimize order delays

Keep every order running smoothly on your shop floor with the proper maintenance cycles. Get notified of work centers and assets that are coming due for maintenance based on actual usage reports and build that maintenance into your daily planning so you can insert it into the best possible place in your schedule. Use Quantum Scheduling to calculate the best time to do the work and minimize any order delays.

see how Quantum keeps your shop in focus

Click one or more areas below to explore.

a single system for production operations

Quantum is a powerful, data-driven manufacturing execution system (MES) platform that helps you control production from the shop floor so you can run your business. By digitizing and connecting your manufacturing operations, Quantum enables you to:

- Increase visibility into every stage of production

- Reduce costly delays and rework

- Drive efficiency with paperless workflows

- Gain real-time control over inventory, quality, and scheduling

Explore the tabs to see Quantum in action

production control

Manage every job on your shop floor on-time without opening a spreadsheet or tracking down a routing. Control the flow of production with job control, priority rules, and live feedback from the floor. Whether you have one big job or 1,000s all at once, Quantum keeps everything running on time and in order.

With Quantum, supervisors don't waste hours chasing down updates or reporting jobs manually, changes work their way through the system automatically. Production stays aligned with delivery commitments, even when urgent jobs or last-minute changes hit. The result: fewer delays, smoother workflows, and higher on-time delivery rates without overwhelming your supervisors. A piece of mind knowing every job is tracked, controlled, and completed profitably.

digital work instructions

Deliver step-by-step instructions directly to operators, customized by part, shift, or line. Attach videos, images, diagrams, text and alternate instructions. Quantum ensures standardized processes and faster training with dynamic, visual documentation. Instead of relying on outdated paper packets or institutional knowledge, operators always have the most current version of instructions at their fingertips. Updates push instantly to the floor, eliminating confusion, wasted work, and costly rework.

Operators work with greater confidence and accuracy, which reduces scrap, accelerates onboarding, and keeps production consistent across every shift. Quantum transforms training and compliance from a burden into a strength.

process tracking

Manage every step of the processes you are running on your shop floor, whether it's a simple routing, a job packet or a complex set of integrated process steps. With Quantum, your team always knows the status of each order—no spreadsheets, no guesswork. Every handoff, approval, and milestone is tracked in real time. Managers can quickly spot bottlenecks, operators know what's next, and leadership has full visibility into progress and profitability.

That means better visibility, faster problem-solving, and the ability to hit deadlines without relying on manual updates. Quantum ensures nothing gets lost in the shuffle, even on your busiest production days.

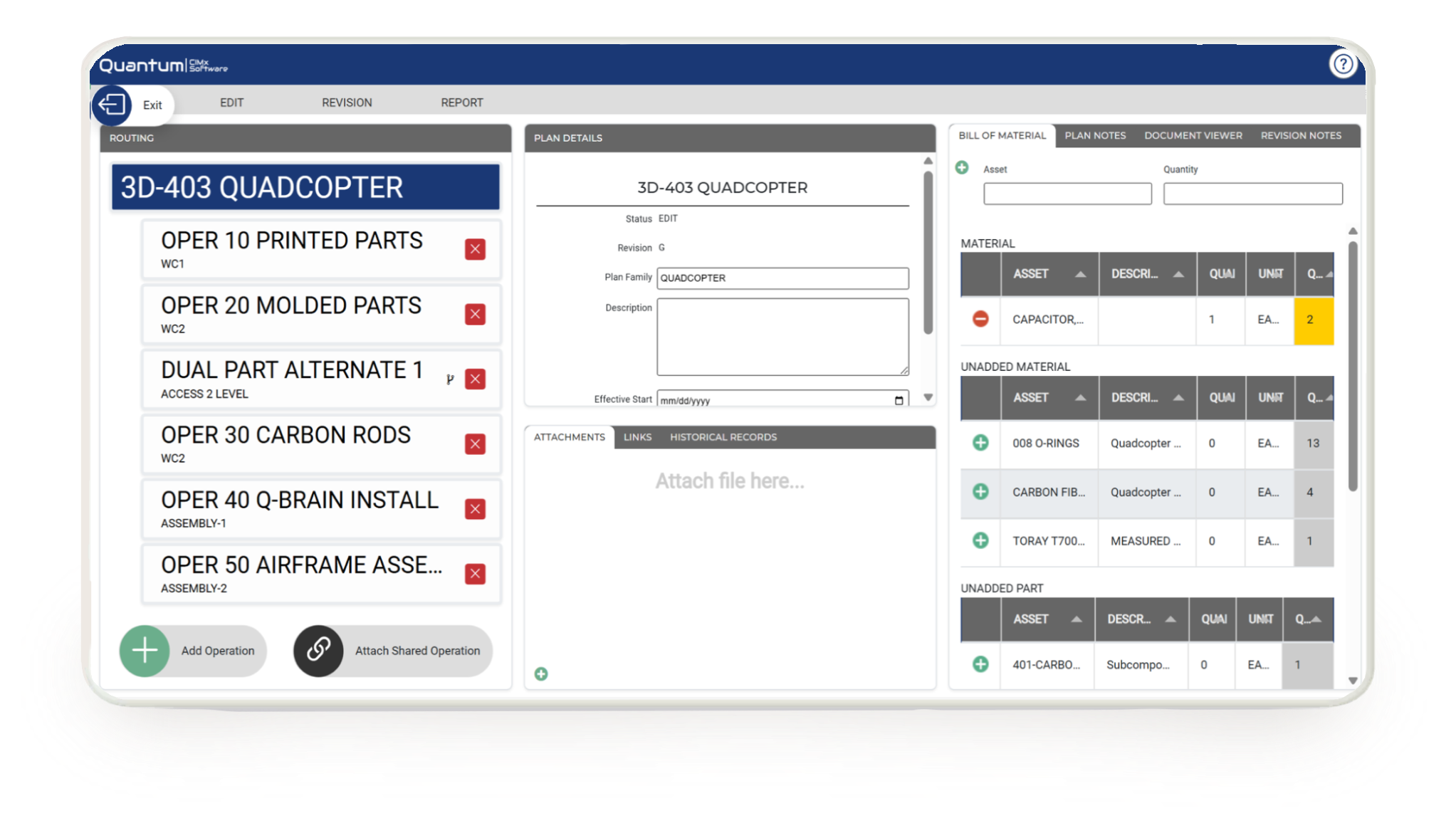

product & process setup

Design your products and build the processes to manufacture them from simple job steps to complex, multi-stage routings. Whether you need basic work instructions or detailed engineering-driven workflows, this is where production begins. Setups that once took weeks can be digitized, tested, and launched quickly in Quantum. Your engineering team can define processes once, then scale them seamlessly across parts, job, and lines.

Quantum ensures that every new product launch or process update starts right the first time, cutting down trial-and-error costs and getting you into production faster. Consistency and repeatability becomes built-in, not an afterthought.

quality control

Demand complete compliance with your processes and your audit requirements. Reallocate work automatically or on-demand with the touch of a button. Capture quality checks, specs, and nonconformances as they happen. Quantum helps enforce quality gates and instantly flags issues—before they hit the customer. Because Quantum integrates quality checks directly into production workflows, quality becomes proactive instead of reactive. Issues are flagged early, so teams can respond immediately rather than after defects pile up.

This reduces rework, improves customer satisfaction, and protects your reputation while making audits simple and stress-free. Quantum ensures quality isn't just inspected, it's built into everything you produce.

.png?width=481&height=267&name=Untitled_Artwork%20(5).png)

alerts

Ensure every member of your shop can communicate with the right team(s) without wandering around. Get real-time alerts for production delays, tool expirations, missed scans, and more. Send alerts or just leave notes for future shifts. With Quantum, your team can act fast—before small issues become big problems. Instead of relying on radios, sticky notes, or word-of-mouth, Quantum keeps communication instant, visible, and logged. Operators, supervisors, and leadership all stay aligned without stepping away from their work.

Instant communication means fewer bottlenecks, quicker recoveries, and a more connected shop floor that runs smoothly across every shift. It's like having a built-in notification system for your shop floor.

production insights

Get an immediate view of the work on the shop floor and its progress towards completion. Make your factory smarter with tools from design through automated data capture. Get the data you need when and how you need it with the touch of a button. Quantum does all the heavy-lifting for you as you do your daily work, gathering real-time data from every corner of your shop, turning it into actionable insights you can use to reduce waste, improve flow, and maximize throughput. No more blind spots or guessing your best move.

This real-time visibility allows managers to make smarter decisions on-the-fly, optimize resource allocation, and confidently commit to customer timelines. Quantum makes your shop more predictable, efficient, and profitable.

production scheduling

Push all your work to your shop floor automatically in the right sequence to make it profitable and know that it will be done on time. Quantum adapts to changes instantly, so you can respond to delays, call-offs, or priority shifts without chaos. Scheduling becomes a living system instead of a static spreadsheet. If one job shifts, everything else automatically adjusts, ensuring resources are used efficiently and deadlines stay intact.

The outcome: schedules that work in real life, higher throughput, and the ability to stay profitable even when the unexpected happens. Your team spends less time managing chaos and more time producing.

machine maintenance

Machine uptime is critical for your production. Get notifications of maintenance due, run planned maintenance and pick the right time on your schedule to do the work. Quantum helps you schedule maintenance proactively based on real machine usage—not just time. Reduce unexpected breakdowns and extend equipment lifespan. Because Quantum ties machine maintenance to actual production data, you can balance preventive care with productivity. Maintenance becomes a strategic activity rather than a disruption.

With Quantum. your maintenance becomes predictable and proactive, keeping your machines running longer, reducing unplanned downtime, and protecting your most valuable assets.

tooling & equipment checks

Get the record-keeping you need to track calibration records and ensure that your tools are properly set for the work you need them to do. Quantum tracks tool usage, calibration schedules, and equipment maintenance in real-time. Prevent tool usage past calibration requirements and really control your shop. Avoid unexpected downtime and ensure every job runs with certified, production-ready tools. Operators no longer need to guess or double-check calibration dates. Quantum makes it simple to confirm tool readiness before work starts, preventing costly errors downstream.

This level of oversight minimizes risk, maximizes tool life, and ensures compliance without slowing down production. Your team spends less time worrying about tool status and more time building quality products.

inventory management

Track every material, part, sub-assembly and tool used throughout production for complete, end-to-end traceability for industry and customer compliance. Quantum provides up-to-date counts, tracking, and reorder alerts, so you never run short or overstock again. With Quantum, inventory isn't hidden in bins or tied up in spreadsheets, it's visible, traceable, and aligned with production needs. You'll always know what you have, where it is, and when to reorder.

You'll cut carrying costs, avoid production stoppages, and gain confidence to bid work knowing materials will be there when you need them. Quantum takes the guesswork out of inventory so you can focus on building, not counting.

a single system for production operations

Quantum is a powerful, data-driven manufacturing execution system (MES) platform that helps you control production from the shop floor so you can run your business. By digitizing and connecting your manufacturing operations, Quantum enables you to:

- Increase visibility into every stage of production

- Reduce costly delays and rework

- Drive efficiency with paperless workflows

- Gain real-time control over inventory, quality, and scheduling

Explore the tabs to see Quantum in action

production control

Manage every job on your shop floor on-time without opening a spreadsheet or tracking down a routing. Control the flow of production with job control, priority rules, and live feedback from the floor. Whether you have one big job or 1,000s all at once, Quantum keeps everything running on time and in order.

With Quantum, supervisors don't waste hours chasing down updates or reporting jobs manually, changes work their way through the system automatically. Production stays aligned with delivery commitments, even when urgent jobs or last-minute changes hit. The result: fewer delays, smoother workflows, and higher on-time delivery rates without overwhelming your supervisors. A piece of mind knowing every job is tracked, controlled, and completed profitably.

digital work instructions

Deliver step-by-step instructions directly to operators, customized by part, shift, or line. Attach videos, images, diagrams, text and alternate instructions. Quantum ensures standardized processes and faster training with dynamic, visual documentation. Instead of relying on outdated paper packets or institutional knowledge, operators always have the most current version of instructions at their fingertips. Updates push instantly to the floor, eliminating confusion, wasted work, and costly rework.

Operators work with greater confidence and accuracy, which reduces scrap, accelerates onboarding, and keeps production consistent across every shift. Quantum transforms training and compliance from a burden into a strength.

process tracking

Manage every step of the processes you are running on your shop floor, whether it's a simple routing, a job packet or a complex set of integrated process steps. With Quantum, your team always knows the status of each order—no spreadsheets, no guesswork. Every handoff, approval, and milestone is tracked in real time. Managers can quickly spot bottlenecks, operators know what's next, and leadership has full visibility into progress and profitability.

That means better visibility, faster problem-solving, and the ability to hit deadlines without relying on manual updates. Quantum ensures nothing gets lost in the shuffle, even on your busiest production days.

product & process setup

Design your products and build the processes to manufacture them from simple job steps to complex, multi-stage routings. Whether you need basic work instructions or detailed engineering-driven workflows, this is where production begins. Setups that once took weeks can be digitized, tested, and launched quickly in Quantum. Your engineering team can define processes once, then scale them seamlessly across parts, job, and lines.

Quantum ensures that every new product launch or process update starts right the first time, cutting down trial-and-error costs and getting you into production faster. Consistency and repeatability becomes built-in, not an afterthought.

quality control

Demand complete compliance with your processes and your audit requirements. Reallocate work automatically or on-demand with the touch of a button. Capture quality checks, specs, and nonconformances as they happen. Quantum helps enforce quality gates and instantly flags issues—before they hit the customer. Because Quantum integrates quality checks directly into production workflows, quality becomes proactive instead of reactive. Issues are flagged early, so teams can respond immediately rather than after defects pile up.

This reduces rework, improves customer satisfaction, and protects your reputation while making audits simple and stress-free. Quantum ensures quality isn't just inspected, it's built into everything you produce.

.png?width=481&height=267&name=Untitled_Artwork%20(5).png)

alerts

Ensure every member of your shop can communicate with the right team(s) without wandering around. Get real-time alerts for production delays, tool expirations, missed scans, and more. Send alerts or just leave notes for future shifts. With Quantum, your team can act fast—before small issues become big problems. Instead of relying on radios, sticky notes, or word-of-mouth, Quantum keeps communication instant, visible, and logged. Operators, supervisors, and leadership all stay aligned without stepping away from their work.

Instant communication means fewer bottlenecks, quicker recoveries, and a more connected shop floor that runs smoothly across every shift. It's like having a built-in notification system for your shop floor.

production insights

Get an immediate view of the work on the shop floor and its progress towards completion. Make your factory smarter with tools from design through automated data capture. Get the data you need when and how you need it with the touch of a button. Quantum does all the heavy-lifting for you as you do your daily work, gathering real-time data from every corner of your shop, turning it into actionable insights you can use to reduce waste, improve flow, and maximize throughput. No more blind spots or guessing your best move.

This real-time visibility allows managers to make smarter decision on-the-fly, optimize resource allocation, and confidently commit to customer timelines. Quantum makes your shop more predictable, efficient, and profitable.

production scheduling

Push all your work to your shop floor automatically in the right sequence to make it profitable and know that it will be done on time. Quantum adapts to changes instantly, so you can respond to delays, call-offs, or priority shifts without chaos. Scheduling becomes a living system instead of a static spreadsheet. If one job shifts, everything else automatically adjusts, ensuring resources are used efficiently and deadlines stay intact.

The outcome: schedules that work in real life, higher throughput, and the ability to stay profitable even when the unexpected happens. Your team spends less time managing chaos and more time producing.

machine maintenance

Machine uptime is critical for your production. Get notifications of maintenance due, run planned maintenance and pick the right time on your schedule to do the work. Quantum helps you schedule maintenance proactively based on real machine usage—not just time. Reduce unexpected breakdowns and extend equipment lifespan. Because Quantum ties machine maintenance to actual production data, you can balance preventive care with productivity. Maintenance becomes a strategic activity rather than a disruption.

With Quantum. your maintenance becomes predictable and proactive, keeping your machines running longer, reducing unplanned downtime, and protecting your most valuable assets.

tooling & equipment checks

Get the record-keeping you need to track calibration records and ensure that your tools are properly set for the work you need them to do. Quantum tracks tool usage, calibration schedules, and equipment maintenance in real-time. Prevent tool usage past calibration requirements and really control your shop. Avoid unexpected downtime and ensure every job runs with certified, production-ready tools. Operators no longer need to guess or double-check calibration dates. Quantum makes it simple to confirm tool readiness before work starts, preventing costly errors downstream.

This level of oversight minimizes risk, maximizes tool life, and ensures compliance without slowing down production. Your team spends less time worrying about tool status and more time building quality products.

inventory management

Track every material, part, sub-assembly and tool used throughout production for complete, end-to-end traceability for industry and customer compliance. Quantum provides up-to-date counts, tracking, and reorder alerts, so you never run short or overstock again. With Quantum, inventory isn't hidden in bins or tied up in spreadsheets, it's visible, traceable, and aligned with production needs. You'll always know what you have, where it is, and when to reorder.

You'll cut carrying costs, avoid production stoppages, and gain confidence to bid work knowing materials will be there when you need them. Quantum takes the guesswork out of inventory so you can focus on building, not counting.

.png?width=400&height=133&name=Untitled_Artwork%20(3).png)

see Quantum in action

Discover how machine maintenance can save time, costs and elevate production across your shop.