Complete Compliance, Quality, Reporting

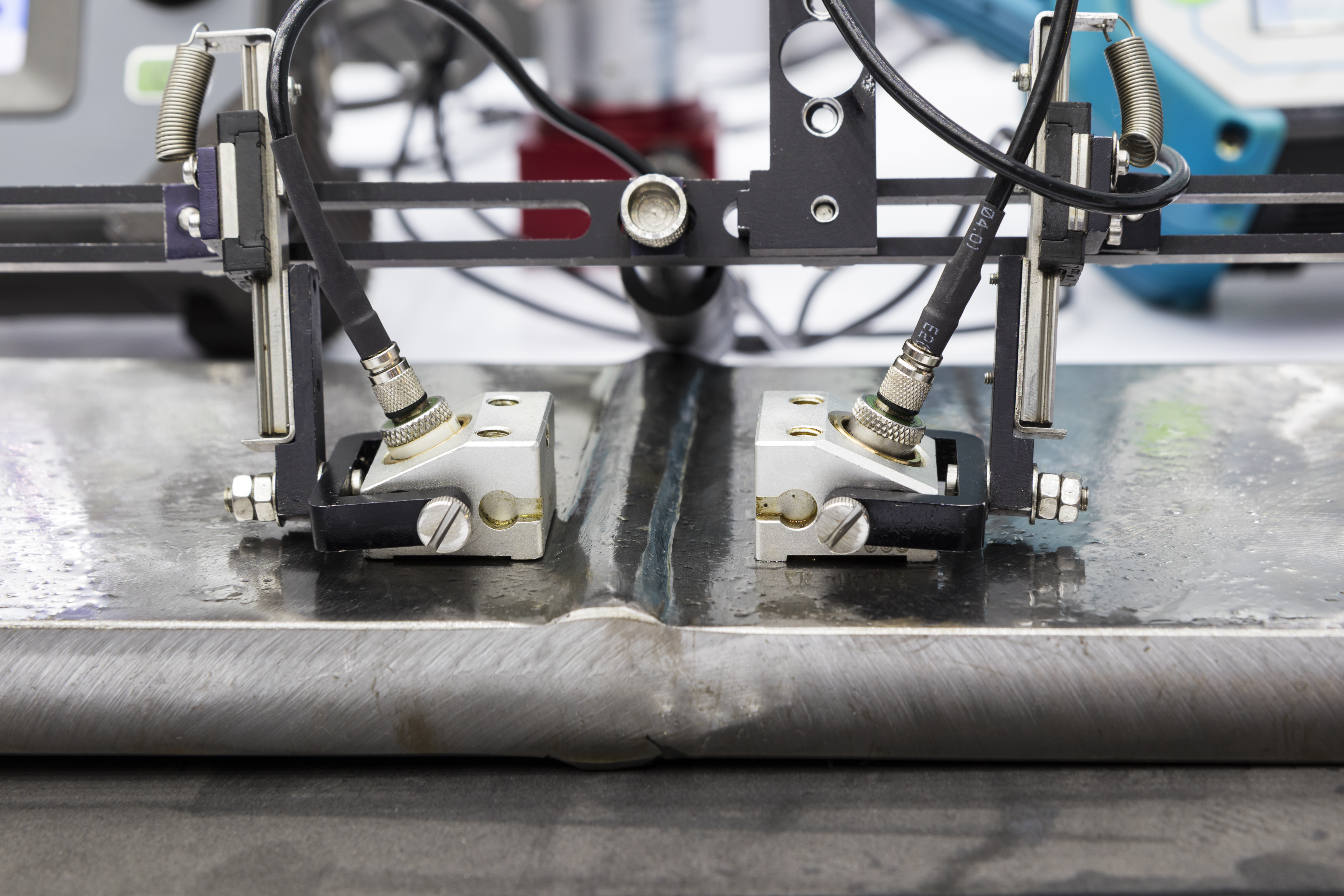

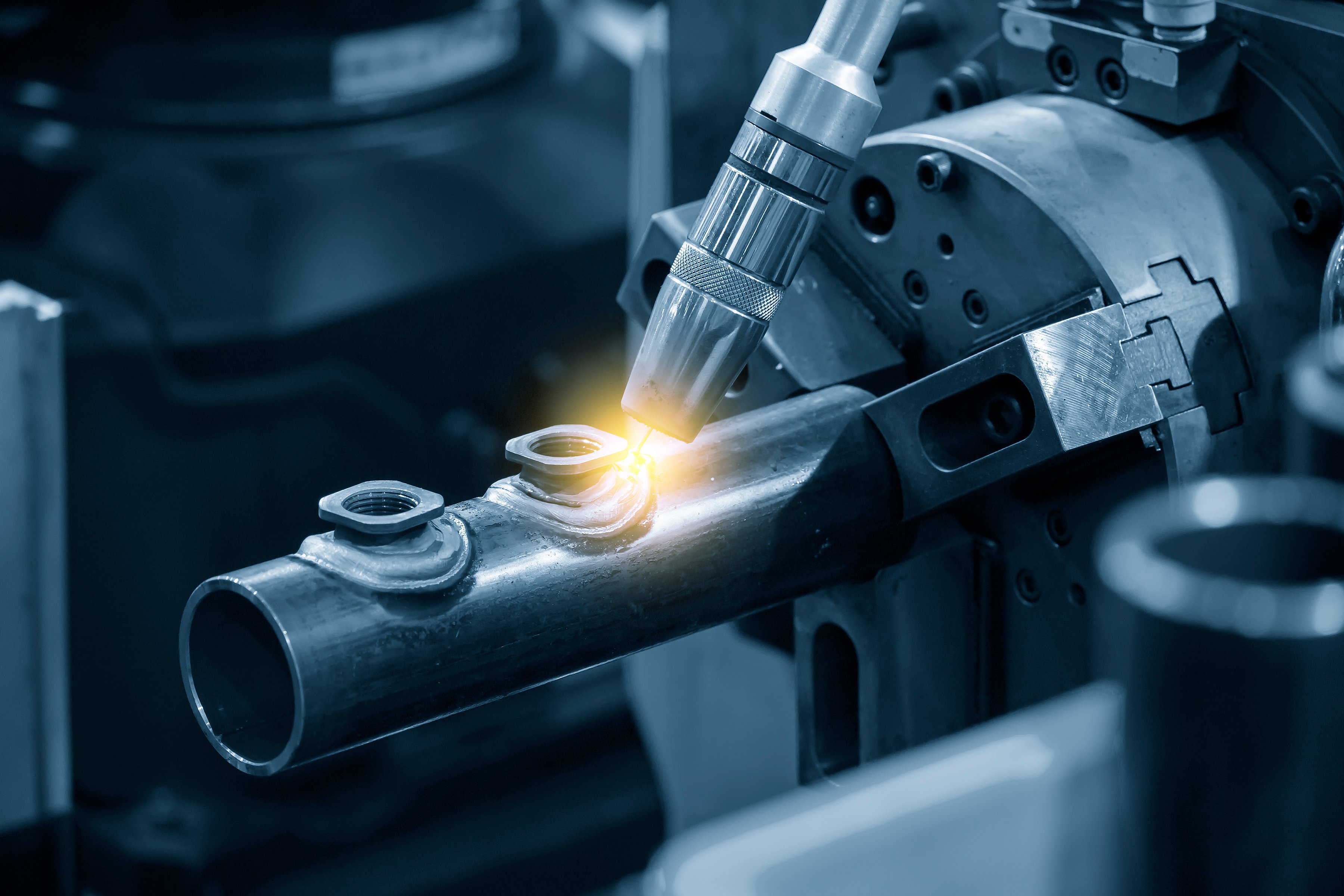

Production Control for Wire Rope and Harness

Cost-effective Electronic Assembly. Win a profitable job every time.

Electronic assembly manufacturers compete on the Engineering of parts; when it comes to production after first article, it's a race to the bottom of price. You need a system that provides the control you need in Engineering and the ability to control costs for your production so you can win both.

Electronic assembly design requires tight controls on the Engineering of the harness and copies of each revision through the prototyping process. Once you move to part production, you need a system that monitors the cost of each assembly and ensures that you are pricing your parts correctly, considering both labor and materials costs in production. Quantum enforces quality, controls costs and tracks every stage of production.

We have 25 years of experience reducing production costs for manufacturers through process and part compliance, cost control and information control. Get a platform that's ready to install today and use tomorrow.

Engineer Your Harness

Build each step of Engineering with control over each revision and auditable records of work and approvals. Quantum has you covered.

Track Your Materials

Create Bill of Materials (BOMs) for each harness and ensure that the proper materials are available at each stage of production. Keep tight control over inventory and wire lengths to avoid over-ordering and under-stocking.

Control Your Costs

Capture the labor and material costs of each step of production, including the costs for non-conforming parts.

Record Your Builds

Capture each step of production with the detailed record of work that you require including in-production inspection records and supervisory sign-offs.

Wire and rope harness manufacturers rely on original article Engineering to make money. These first article builds can be greatly profitable if you are able to monitor the number of Engineering Change Orders (ECOs) required to produce an approved assembly. On paper, this is next to impossible. Many manufacturers turn to Microsoft for help. Access and Excel databases are not controlled and will not give you the compliance you require.

Quantum gives you complete Production Control so you get your job done on-time, within a steady profit margin and compliant to every step of the process.

Quantum is built for today so you're ready for tomorrow.

Every Quantum installation prepares you for today, tomorrow and the future with instant access to real information about the work you're doing. Abandon your template-based sheets. Get rid of your white boards with production schedules. See how Quantum can help you build, control and maintain your shop.

We pride ourselves on providing the best customer service on the planet.

We believe it separates great companies from everyone else. And you can't run your shop with just anyone.

0%

Time Savings

0%

Average Increase in Quality

0%

Ability to Connect with Us Directly