WHY PARTNER WITH CIMX?

Help your clients increase the speed, accuracy, and quality of their manufacturing process with tight Production Control

Built for manufacturers. Structured for partners.

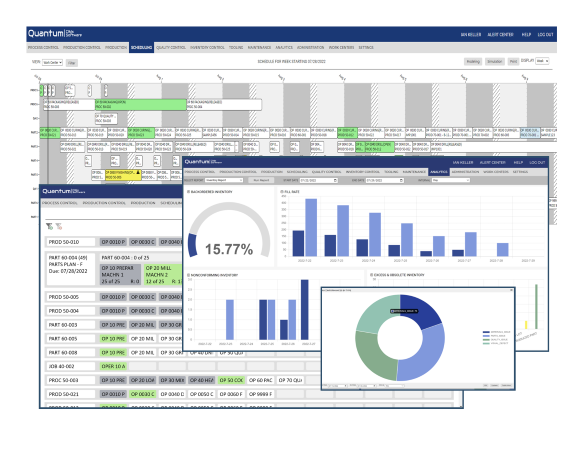

We built Quantum MES to handle the problems your manufacturing clients have today: to tell them where everything is in process, to warn them when something is falling behind, and help them solve their production problems more rapidly and cost-effectively.

Together, we can provide greater value by connecting more areas of the shop floor and increasing visibility, control, and efficiency for manufacturers.

If you have a client looking for a time and cost-effective Production Control solution, Quantum is it. CIMx has a proven method to get them moving faster towards automating their shop floor data and processes with measurable metrics and goals. Ask us about it.

We will work hard to understand your capabilities and/or product to increase the footprint for our combined offerings. Are you as passionate about manufacturing as we are? If so, let's connect!

Tighten their processes.

Having the right information makes all the difference in manufacturing. Quantum gives your clients a true connection to the work on the shop floor, whenever and wherever they need it. Quantum collects, filters and puts their information where they need it at the right time.

Connect their systems to manufacturing.

Connected data is actionable data, especially when you're helping your clients with a Lean, Six Sigma or continuous improvement project. Quantum can connect to any ERP at your clients' site, even one that's homegrown or on a VAX. We have the tools to help you help your customers.

Improve their manufacturing workflows.

From dispatching to production scheduling, quality control to engineering, Quantum provides automated and manual workflows for your clients. Help them to spot trends in their work and tighten their processes with the right data to get them there.

How does QUANTUM solve manufacturing issues?

No more FAIL AND FIX scenarios in your client's shop. Not with Quantum. It's focus is to CONTROL and PREVENT issues, spotting things that are going wrong and giving your clients immediate access to approved workarounds so they can get back to it quickly. When something completely unexpected happens like machine failure or a materials issue, Quantum handles those too.

Sometimes, the issue is good, like a Change Order or a Rush Order from an important customer. Quantum handles these routinely with minimal disruption to the current order flow. Your client can even simulate work in Quantum to see if they can accommodate that Rush Order before they accept it. Quantum dynamically re-assigns work to optimize their workflows and meet their shipping needs.

LET'S DISCUSS PARTNERING TODAY

WHY WE ENGAGE

Partnerships, for us, are about repeatable, value-added activities. We have solutions for you and a platform for your clients and customers. From Six Sigma or Lean consultants to software companies that need to add critical capabilities to their platforms, we deliver the platform (and groundwork) for Industry 4.0 manufacturing.

HOW WE ENGAGE

For consultants, we work to understand your business model and your core client. We have a product that gives you the information you require from your clients to provide value-added consulting services on Lean, Six Sigma, Continuous Improvement and Productivity.

For software companies, we learn about your own platform and what you need to extend your customer offering. We have a platform that integrates easily and provides a wealth of data for you to either offer your customer or use to enrich your own product platform.

THE QUANTUM PLATFORM

The Quantum MES platform is a full Manufacturing Execution System (MES). It has the functionality from inventory to process and part management, scheduling to tool calibration, reporting to analytics. Whether it's complex, multi-step manufacturing to assembly of mass-manufactured parts, from enterprise to small contract manufacturers and job shops, we have the Industry 4.0 tools manufacturers need. It installs within an hour or two on-premise for manufacturers who can't afford the on-going costs of cloud offerings or the risks associated with putting their product designs out there.

SYSTEM CONNECTIVITY

You don't need to connect Quantum to anything. It can run your design and dispatch your work without any additional information. However, most customers do connect it to an ERP or at least one other data source to expand their data use.

WHAT WE CAN ACCOMPLISH TOGETHER

We have enjoyed amazing partnerships since we started the company in 1996 and have over 25 years of experience in Production Control helping manufacturers increase accuracy, efficiency, and capacity. We treat each partner individually, based on what you require, but all of our partners require either a platform to get data from their clients or a product to increase what's possible for their customers. Either way, Quantum is the solution. Let's talk.

Let's talk further about Partnering

From partnership to lead generation to white label, we've done it all. Ask us about the model that you need.