Complete 21CFR Compliance, Quality, Reporting

Production Control for Medical Device

Material and Tool Compliance from Calibration to Labeling and Reports.

You need compliance and the written proof of it for every part you make and label in Medical Device. Whether you are making parts to stock or parts to Order, you need to know that every tool you used and every material you consumed is both correct and recorded.

From production build to packaging, you need to know that you have every record you need for auditable control of your work. Once you put an Order on the shop floor, you need to know that you can control the work, right down to every step in the process. Quantum enforces quality, directs accurate workflow and delivers compliance at every stage of production.

We have 25 years of experience ensuring that medical device companies have the Production Control they require for compliance. Maintain all of your certifications including 21 CFR part 11 with a platform that's ready to install today and use tomorrow.

Engineer Your Parts

From original Engineering, through revision control and auditable records of work and approvals, Quantum has you covered.

Specify Your Materials

Create part-specfic Bill of Materials (BOMs) for each part and ensure that the proper materials are available at each stage of production.

Certify Your Work

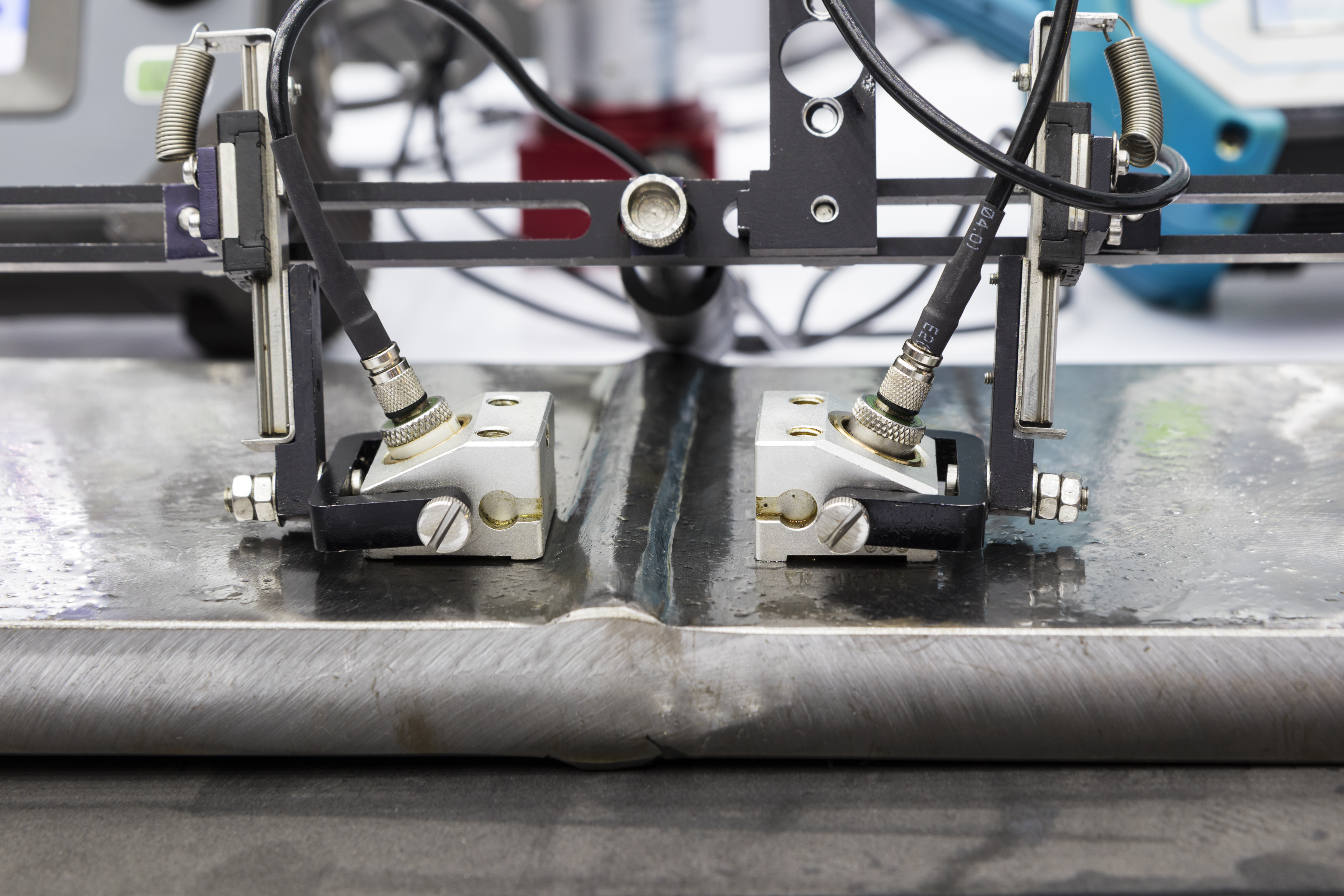

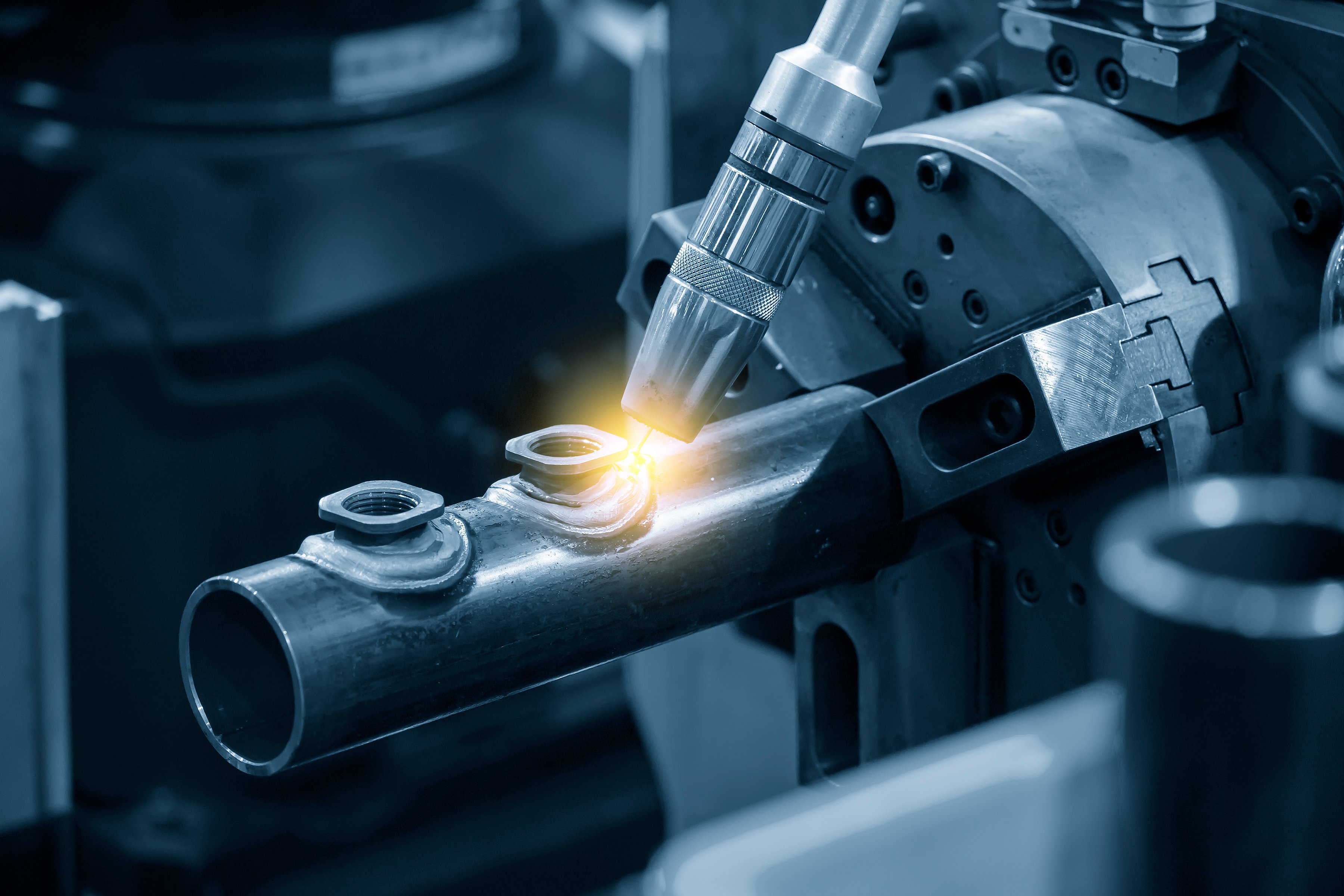

Comply with each equipment requirement for each customer with controlled work paths for each part on your shop floor and certification of Operators.

Resolve Your Issues

Correct each production non-conformance and push automated rework routines to the proper place along with approval of each piece of rework.

Record Your Builds

Get an automated eDHR with a record of every piece of work that was done on every serialized part from the original Engineering through to every Operator that touched the part in production including in-production inspection records and supervisory sign-offs.

Medical Device manufacturers need a complete auditable record of every piece of work they do, from the moment the Order is placed to the placement of the label on each part, carton and shipping box. Many manufacturers use common programs and specialized label-makers to get there. An approach like this does not give you the seamless process control you need for a proper eDHR.

Our Quantum Production Control platform gives you everything you need to get your parts compliant in both production and labeling.

Quantum is built for today so you're ready for tomorrow.

Every Quantum installation prepares you for today, tomorrow and the future with instant access to real information about the work you're doing. Abandon your template-based sheets. Get rid of your white boards with production schedules. See how Quantum can help you build, control and maintain your shop.

We pride ourselves on providing the best customer service on the planet.

We believe it separates great companies from everyone else. And you can't run your shop with just anyone.

0%

Time Savings

0%

Average Increase in Quality

0%

Ability to Connect with Us Directly

.png?width=480&height=149&name=CIMx-logo-transparent%20(1).png)