Quantum provides

Production Visibility for Manufacturing Control

INCREASE CAPACITY AND PROFIT

Critical decisions are part of your job as a manufacturing executive. Whether it’s missing inventory, a supply chain issue, workforce problems, or an out-of-control schedule, you need to make accurate decisions to keep production on track and costs down.

Do you have the reliable information you need to make those decisions? When you have full visibility and real-time manufacturing data, then Complete Production Control is possible. You need a system that analyzes and presents this data in an easy-to-understand way, providing you with the capability to leverage that insight to successfully manage work.

You need Quantum™.

INCREASE EFFICIENCY

DO MORE WITH CURRENT CREW

CONTROL INVENTORY

HAVE THE STOCK YOU NEED

IMPROVE ACCURACY

GAIN THE INSIGHT YOU NEED

Key Manufacturing Executive Features in Quantum

With production insight and accurate information, you can guide your team with confidence – that’s data-driven decision-making. That’s Quantum.

-

Real-Time Production Reporting and Dashboards: Check and track production status anytime. Leverage manufacturing automation for notification when an order is in danger of shipping late. Improve customer confidence with on-time shipments.

-

Flexible and Accurate Production Scheduling: Keep the lines moving. Push work to the floor automatically, in the right sequence, and with the correct information, so you know it’s done right the first time and on-time.

-

Faster Business and Production Results: Quantum is easy-to-use, with regular training for you and your team. Quantum helps your team do more, supporting their work, while you have the data and control to execute your business goals. Increase profit and capacity by controlling cost, waste, and improving shopfloor management.

-

Manufacturing Data and Insight You Can Use: Take the pulse of your manufacturing with Quantum. The system links all facets of production. Collect, review, use, and manage production information so you can see the big picture and plan work with confidence.

-

Inherently Move Towards Improvement Initiatives: Quantum supports Six Sigma, Lean, and Industry 4.0 initiatives by giving you tools that improve efficiency, reduce waste, and increase productivity.

Adjust quickly as change happens. Optimize production schedules and minimize downtime by leveraging Key Performance Indicators (KPIs). Centralize production control and reporting in a single system. Adjust and optimize your schedules, then update the shop floor automatically – it’s all handled in Quantum.

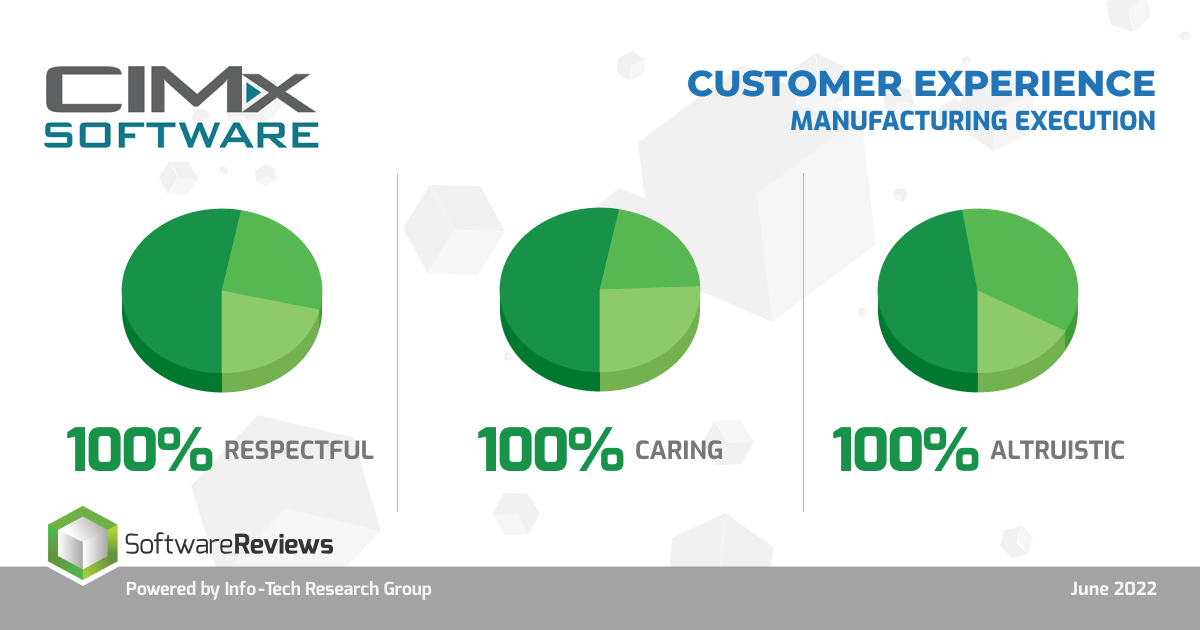

Our customers have spoken

In the 2022 InfoTech Research Group MES Software Survey, vendors were assessed by their own customers on what it was like to work with them. We are honored by what the survey results revealed.

.png?width=300&height=67&name=Quantum-4%20(2).png)

The Complete Production Control Software for North American Manufacturers

CIMx has a long history of collaborating with manufacturers in the following industries to provide the solution needed to improve visibility for production control.

Manufacturing Software Made for Modern Production

As an executive, Quantum gives you everything you need to solve problems, boost production, and cut costs. Your production team has the information and control they need, while you have the visibility and data to make better business decisions.

INCREASE PRODUCTION EFFICIENCY

Boost production without adding costs. Produce more with the resources you have. Tough goals come with the job of managing a manufacturing team, and you need a system that can help.

Quantum provides an overall view of production as well as the granular data and information on every order. You can see opportunities and dig into the problems to find solutions.

With Quantum, you know how to increase efficiency.

- Notifications alert you to problems in production, giving you time to adjust work to ensure product ships on time.

- Capture production and process information to improve overall manufacturing throughput.

- Provide the process enforcement and quality checks to maintain first-time built quality.

Quantum captures and analyzes your production information, providing insight to increase productivity and capacity, discover latent problems, improve processes, and automate training. With production visibility, everyone is empowered to increase performance.

With Quantum Scheduling, you can accommodate changes and still meet commitments. Adding a rush order or increasing quantities with existing orders are not as stressful when you can accurately model and predetermine how the change will affect your current schedule. Increase control of your schedule and find ways to further increase capacity.

Control Inventory to Control Production

Inventory is the second largest cost center for manufacturers, and supply chain issues are creating production pain and higher costs.

Stay a step ahead of problems and minimize the pain with accurate, up-to-the-minute inventory numbers. Forecast need and track usage so you have necessary stock on hand. Trace the materials used at the parts, sub-parts, and finished goods level, then manage inventory from receiving to shipping. Make sure you have on hand accurate inventory ahead of production needs.

With Quantum, you have the control and end-to-end visibility you need to manage inventory.

- Quantum has tools to integrate with your ERP, so you can customize the integration and close the loop on tracking and managing inventory.

- Attribute assets to a job or customer when you accept them into inventory, ensuring you have what you need to complete work

- Lot and serial number management provides end-to-end traceability records on both inventory and orders.

Quantum provides you up-to-the-minute inventory usage information from production planning and scheduling to the builds already in process on the shop floor. Uncover hidden costs, eliminate panicked purchasing and excessive freight charges, and keep your inventory stocked and lean.

Accurate Data enables Process Improvement and Resource Management

Are you working proactively, driving process improvement, and managing work, or are you reacting to problems, constantly dealing with emergencies and handling problems rather than growing your business?

Problems occur when you don’t have timely, accurate information. You can’t improve if you don’t see an issue until it’s a disaster on the shop floor and orders are in danger of not shipping. If your production team is guessing while they work, or scrambling to find information, then errors will happen.

Quantum is specifically designed for manufacturing. It collects, manages, and analyzes your ever-changing shop data so you and your team have access to current and accurate information. Every department has the information they need, and they’re notified of issues that would impact meeting customer demands.

With Quantum, you can better manage the most demanding and complex production cycles.

- Actively manage your production schedule with confidence using accurate, timely information.

- With everyone working from a single, shared, and accurate source of information, you can eliminate mistakes and incorrect planning.

- Select, collect, and record relevant shop data collection to track production, capture best practices, and fuel process improvement.

Quantum connects you to production, collecting and analyzing data to provide you with the accurate information you need to make critical decisions and maintain quality, contain resource costs, and improve efficiency.

Quantum: The best Manufacturing Executive Software

Ready to Get Started?

Connect WITH CIMx Today!

Contact us today to schedule a brief, no-obligation meeting with our own staff to discuss your needs and how Quantum can help.

.png?width=480&height=149&name=CIMx-logo-transparent%20(1).png)