Developing a Vision of Paperless Manufacturing and MES

Understanding the CIMx Vision for Paperless Manufacturing offers an insider’s view of what drives us to make the best product for our customers, and...

2 min read

David Oeters : July 18, 2013 at 5:33 AM

As manufacturers struggle to find qualified shop floor workers, it’s not enough to hope secondary education will improve. It’s time to start finding solutions ourselves.

A recent survey by The Chronicle and the American Public Media Marketplace shined a light on the struggles manufacturers face when hiring qualified employees. In an article reviewing the survey, hiring managers described potential candidates as, “woefully unprepared,” saying they lacked, “basic workplace proficiencies,” or even the, “ability to solve complex problems.” Assessments such as these do not bode well for the future of manufacturing.

It is easy for businesses to blame higher education. According to another article, “In 2008, the Boeing Company ranked colleges based on how well their graduates performed within the corporation.” Some blame does rest with education programs, but not all of it.

Technology and processes are continually adapting. New tools are constantly shaping the workplace. Many companies struggle internally to adapt to these changes. It is unrealistic to expect education to incorporate change any quicker. Additionally, new employees struggle with entering organizations where information is secularized in Information silos. Many times, new employees replace retirees, and have no access to the critical company information contained in those silos – silos that are many times reflect the accumulated knowledge of the retiring employee.

Solutions to the Qualified Worker Crunch for Manufacturing

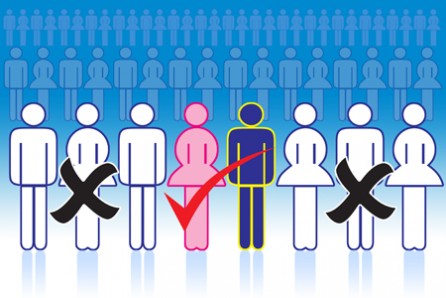

As we look for solutions, we should start with how we are currently managing corporate information. No matter the source of the “worker crunch,” there are ways businesses, especially manufacturers, can help prepare new employees while improving current operations. The goal should be getting the right information to the right people at the right time.

For example:

Successful companies begin with an effective workforce. While it is easy to cast blame for the worker crunch, there are steps a smart business can take to ensure new employees have the greatest chance of success.

Those steps start by capturing, managing and distributing information and eliminating information silos, and will improve production, increase quality, and benefit employee morale.

Next Steps

Connect with a CIMx Application Expert today and learn more about controlling your shop floor with the MES designed for your industry, Quantum.

Understanding the CIMx Vision for Paperless Manufacturing offers an insider’s view of what drives us to make the best product for our customers, and...

1 min read

Customers often ask us how we can ensure the accuracy of our project estimates and budgets. Our answer is simple – Agile. By David Oeters, Corporate...

Market acquisition is changing the manufacturing software solutions market, but not always for the better. We take a closer look at its cost to...