1 min read

Being Competitive in 2021

I heard someone in an interview the other day say consumers wanted things to return to pre-COVID levels. The speaker believed that people didn’t care...

Over the summer, we want to start a conversation around the tools you provide your workforce to help you be more profitable. We’re naturally going to spend time talking about an MES, as that’s what we know most about, but also ERPs and other tools, including huddle topics. We’re basing the conversation on the areas of most typical waste in a shop floor. We started with inventory.

In manufacturing, you need to know your inventory. At all times. Inventory is defined as a comprehensive list of the goods in a building. If you don’t have a firm handle of the number of assets you own, where they are and when you use them, you are wasting money daily and may even need to inventory your inventory, meaning physically count and make a listing of. In the last 3 months, I have talked to 3 companies that physically count their inventory every month because their ERP just can't keep track. Read more about how to solve this problem here.

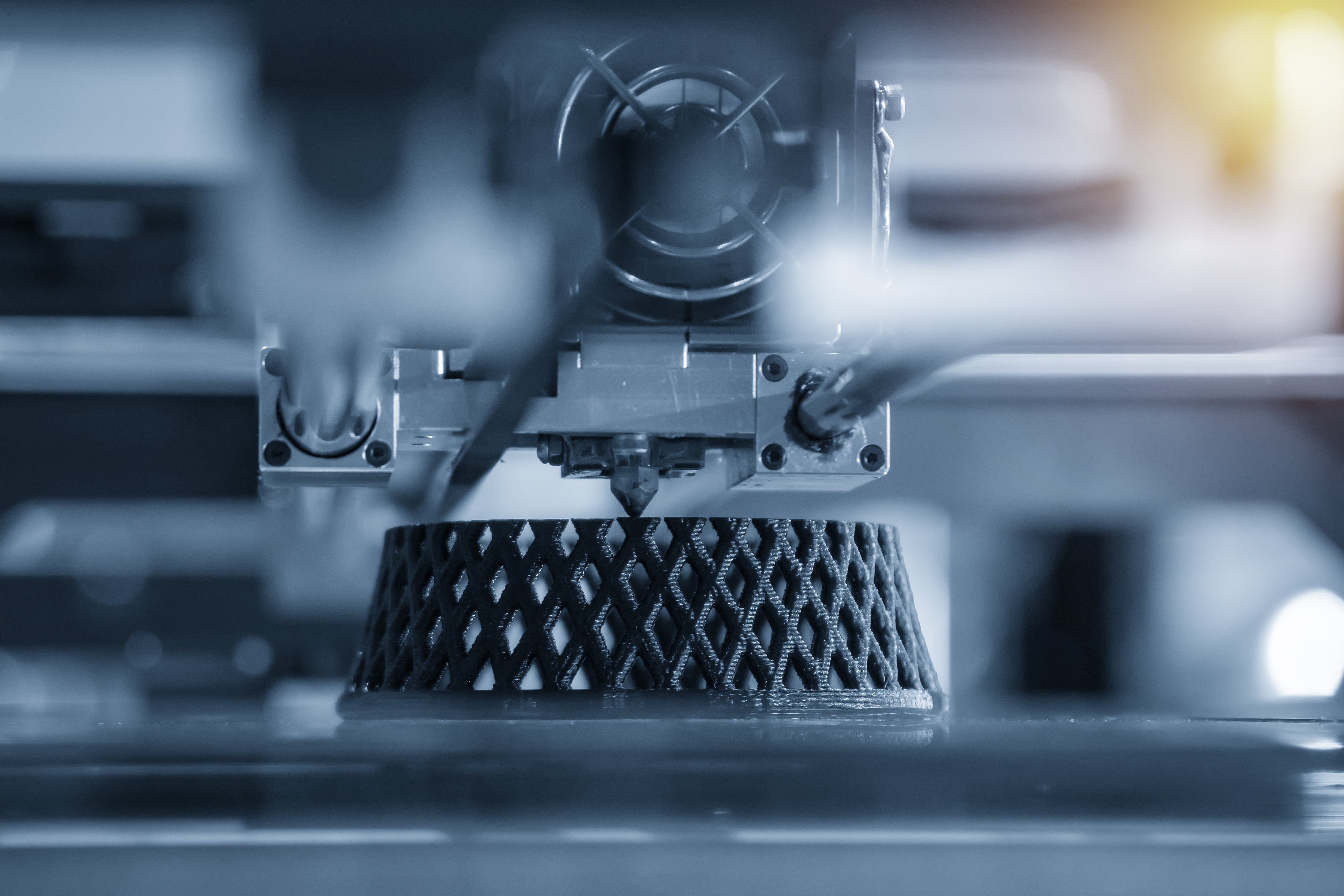

Depending on the industry you serve and the value of your raw materials and finished goods stock, inventory may rival or surpass your workforce as your most expensive and valuable asset. Especially in the field of metallurgy and composites, both raw and finished goods are cost-intensive and storage space for such things can also be at a premium.

Later this summer, we’ll talk about over-production. These are intimately connected. For those of you who build to orders, you need the right inventory to complete and ship orders on time. For those who are in build to stock, you must know exactly how much you need to avoid producing more than you should.

The number one issue we hear from companies, bar none, is that their ERP is not handling their inventory. They talk about being able to purchase goods and even services from vendors, but not actually knowing if they bought the right thing, if it will be there when they need it or if they have the right amount. In the case of outsourced services like specialty processing (chroming) or using an outside job shop to perform something you can’t, there’s also an issue with lead times. (We’ll talk about this more when we talk scheduling in a later blog.)

Inventory is intimately connected to your schedule. Without proper inventory, you will have work stopped, delayed, even dead-headed in the aisle. We’ve talked about this before, and it seems obvious, but it’s not something that ERP vendors can handle – manufacturing moves. All day. Predictably and not. And you have to be prepared for it all. The movement of inventory, people and work on the shop floor is challenging or impossible for a system that counts things, like an ERP, to do.

There’s a lot to talk about here when you’re discussing inventory and profit. Let’s break it down one issue at a time and dive a little deeper into where you spend your money – purchasing inventory - today.

Raw materials are valuable to both you and your customer. To your customer, they determine, or should, the price of what you produce. If the market you’re in is driving your price down in a commodity spiral, how low will you know you can go on your per-product price? It should be based on the cost of both your raw materials and the people and machines or tools you will use in the process. Where can you substitute a less expensive material to win the deal?

Can you time inventory delivery properly to the work you have? You will need to know your consumption rates over time and establish upper and lower thresholds for each material so you do not over- or under-stock these goods.

If you have a certification process for the materials that arrive at your receiving dock, you need to think about how and where you keep the proof of a passing certification on file and how and where you track the use of that inventory in production. This is tricky or impossible in the ERP. You can certainly attach a file. In the software industry, we call this “paper on glass.” A pdf does you little good when you’re trying to track use of a material. You need a system or process to track the use of materials as applied to the orders that you’ve produced with them. This is traceability and it closes the gap on the certification that you do.

Let’s continue next week with your people as an asset. How do you track the work they’re doing, utilization and efficiency?

We believe in the critical importance of manufacturing for companies of all sizes right here in North America. We are a software company that believes in standard toolsets affordable for shops from 20 to 200. We believe in finding manufacturers the tools they need to work, whether it's a simple Google doc, an Excel sheet or a Production Control system. To learn more about meeting your targets for 2021 or just getting a question answered, visit us at CIMx Software.

1 min read

I heard someone in an interview the other day say consumers wanted things to return to pre-COVID levels. The speaker believed that people didn’t care...

We’ve all heard the news stories of employers that are not able to fill jobs. It’s been a challenge for all segments of the industry. Even in areas...

This summer, we’ve been talking about profitability. Who doesn’t want more of that? Last week, we talked inventory. Over- and under-inventory issues...